Technical parameters

| TYPE OF FINISHING | LACQUER | OSMO OILWAX |

|---|---|---|

|

|

| |

| SHELL |

|

|

| MECHANICAL DAMAGE |

|

|

| WATER AND DIRT |

|

|

| RENOVATION |

|

|

| CARE AND MAINTENANCE |

|

|

- All FINISH PARQUET and FINISH BOARD are available in oilwax version.

- To finish them off we use OSMO oilwax and what’s most important, only those products – of all available on the market of oilwaxed floors – have 3 layers. It is machines applied and UV hardened.

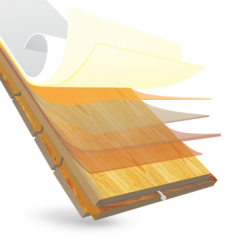

- Single-fin top layer accentuates aesthetic and visual qualities of our products and by using newest production technology we can ensure you, that our products are of highest quality. Particular slat layers are glued perpendicularly , they eliminate natural stress and distortions, typical for big, solid elements.

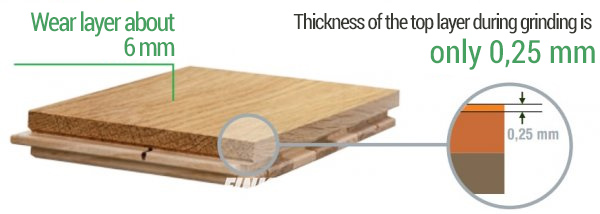

- Top layer is covered with natural oilwax or lacquer. Lacquer hardened using UV method is permanently adhered with wood, which prevents it from cracking and peeling off. Thanks to glueing staves directly to the substrate, we can avoid the resonance effect. Parquet staves are machine grinded (not traditionally on the floor) which results in the floor being processed with tolerance corresponding with ready parquet standards.

- Thickness of the parquet – 14mm enables – without additional adjustment – joining it with ceramic tiles and thermal transmittance of the wood enables to use underfloor heating.

- Size of FINISH PARQUET thickness 14mm, width 70mm, length 490mm

- Size of FINISH BOARD thickness 14mm, width 140 or 150mm, length 900-1200mm

- Thickness of top layer – about 6mm

- Wood specie of the bottom layer – hard, leaf wood

- Amount of lacquer layers – acrylic resins free from formaldehyde

- Alternative finishing – OSMO oilwax

- Hardening method for lacquer and oilwax – UV radiation

- Possibility of floor sanding – multiple

- Installation types – glueing all elements to the substrate, without glueing tongue-and-groove

- Glueing to the substrate – water free adhesives recommended by floor producer, suitable for glueing lacquered parquets

- Possible patterns – herringbone, brick, double herringbone, double brick, squares, marine floor, mixing different types of wood species

- Possible substrates – just like substrates for wooden floors:cement floor, anhydrite floors, chipboards and plywood

- Applicable – every room except bathrooms

- Brushing

In accordance with the latest trends, brushing gives us a visual effect of an old looking wood. This effect makes our floor look more valuable, as it is one hundred years old. Brushing the soft structure and leaving the hard one, enhances natural structure of the wood grains and fiber arrangement. Additionally brushing alsomakes eventual marks and traces of use less visible. Brushed wooden floors matches perfectly with rustical style but also looks good paired with modern, designer interiors. Brushing is usually paired with oiling and four-sided beveled finishing.

In accordance with the latest trends, brushing gives us a visual effect of an old looking wood. This effect makes our floor look more valuable, as it is one hundred years old. Brushing the soft structure and leaving the hard one, enhances natural structure of the wood grains and fiber arrangement. Additionally brushing alsomakes eventual marks and traces of use less visible. Brushed wooden floors matches perfectly with rustical style but also looks good paired with modern, designer interiors. Brushing is usually paired with oiling and four-sided beveled finishing.

- Tinting

Wide range of staining options, from brightest whites to dark, coal colors allows us to obtain a perfect shade of the wooden floor. Staining can be used to emphasize the natural wood structure and its color or on the contrary – it can lead to a totally new look. Unlike heat-treated or smoked floors – staining is a process of surface dyeing and so the renovation (sanding) easily restores floor’s natural color. ( There is a possibility to use the same staining color or a totally new one we choose).

Wide range of staining options, from brightest whites to dark, coal colors allows us to obtain a perfect shade of the wooden floor. Staining can be used to emphasize the natural wood structure and its color or on the contrary – it can lead to a totally new look. Unlike heat-treated or smoked floors – staining is a process of surface dyeing and so the renovation (sanding) easily restores floor’s natural color. ( There is a possibility to use the same staining color or a totally new one we choose).

- Chamfering

FINISHPARQUET offers floor finishing without chamfering (look similar to the one after sanding) or four-sided chamfering (refraction of the edges from four sides). It is a reference to traditional floor installation, where you start from long, solid elements made entirely from natural wood. Four sided chamfering gives the floor a very distinctive character. With this method eachstave or board is separated and displaye, which emphasizes the real, natural floor construction.

FINISHPARQUET offers floor finishing without chamfering (look similar to the one after sanding) or four-sided chamfering (refraction of the edges from four sides). It is a reference to traditional floor installation, where you start from long, solid elements made entirely from natural wood. Four sided chamfering gives the floor a very distinctive character. With this method eachstave or board is separated and displaye, which emphasizes the real, natural floor construction.

- Heat treatment

Heat treatment, also known as post curing, is a process of modifying wood with high temperatures and water steam. Thanks to this, we receive a material with totally changed, new qualities. Sugar is caramelized in wood and because of this process, the wood obtains its typical dark color that resembles different exotic wood specie. Heat treatment process also leads to reducing water absorption which at the same time eliminates bacteria and fungus growth. Dimensional stability increases. It’s a totally pro-eco process which guarantees homogeneous staining throughout of the whole board.

Heat treatment, also known as post curing, is a process of modifying wood with high temperatures and water steam. Thanks to this, we receive a material with totally changed, new qualities. Sugar is caramelized in wood and because of this process, the wood obtains its typical dark color that resembles different exotic wood specie. Heat treatment process also leads to reducing water absorption which at the same time eliminates bacteria and fungus growth. Dimensional stability increases. It’s a totally pro-eco process which guarantees homogeneous staining throughout of the whole board.

- Smoking

Smoking is a process of chemical wood treatment (ammonium in gaseous state under high pressure) to obtain dark wood color. Contrary to using staining, which only colors the surface, smoking changes the color of the whole element ( just like heat treatment process). Color is secured alsi in the renovation process but there is a possibility to change it by using staining.

Smoking is a process of chemical wood treatment (ammonium in gaseous state under high pressure) to obtain dark wood color. Contrary to using staining, which only colors the surface, smoking changes the color of the whole element ( just like heat treatment process). Color is secured alsi in the renovation process but there is a possibility to change it by using staining.

CAUTION!

- HEAT TREATED WOOD IS NOT UV RESISTANT AND GRADUALLY THE COLORS BECOMES LIGHTER.

- THE PRODUCER IS NOT RESPONSIBLE FOR ANY NATURAL CHANGES THAT MAY APPEAR ON FLOORS MADE OF EXOTIC WOOD, ESPECIALLY BLEMISHES.